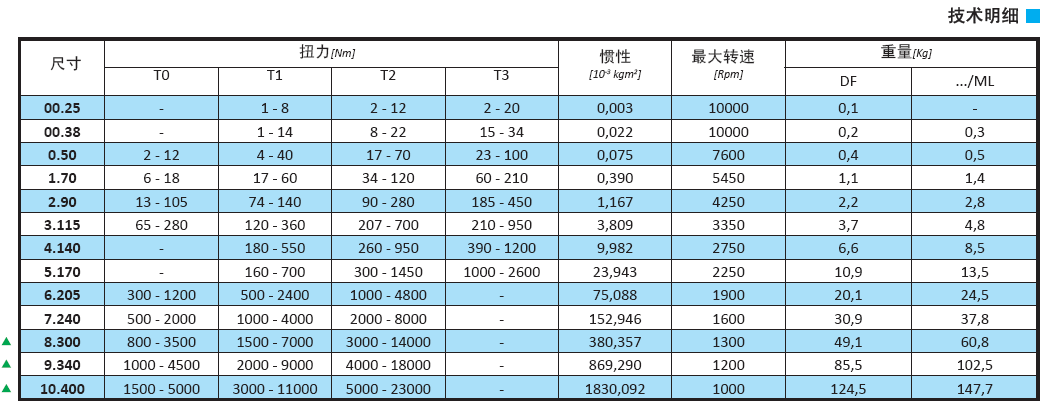

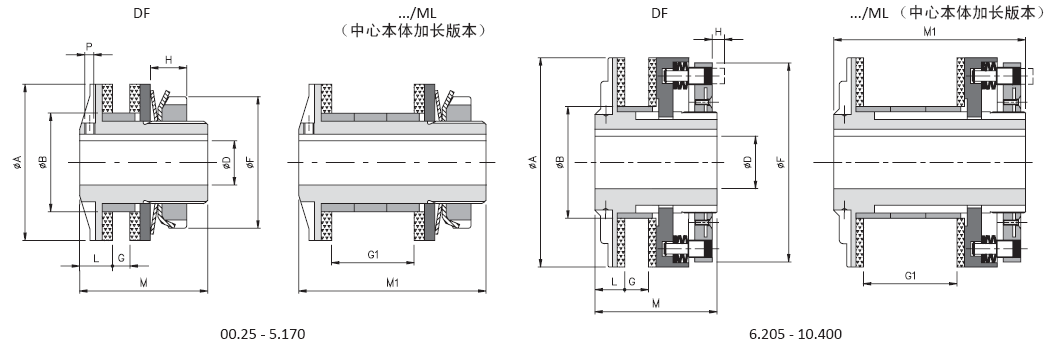

A sprocket, pulley or other transmission component in the friction torque limiter is mounted between the two slides. When torque is reached, it ensures that continuous drive is achieved without damaging the components. One of the features of the device is: lower protection costs

Simple and economical friction torque limiter.

Suitable for working in dust conditions, no speed regulation is required between the gearbox and the output device.

No noise, no vibration.

Rotate two-way protection.

Non-asbestos friction disc.

The torque setting is simple and precise through the locking ring adjustment.

The “H size” innovative calibration system provides instantaneous calibration of the equipment.

On demand

Complete gear shifting, all turning and installation (sprocket, pulley, gear pair).

A variety of friction discs for specific applications.

Can be connected to openings and keyways, locking assemblies or other locking systems.

The surface layer is treated with anti-corrosion treatment to meet special requirements.

Advantages and characteristics

Protect the motor gearbox in an accidental collision.

When the stress is too high, the baler film can be protected.

The static torque is protected without causing detachment.

The gear is protected during short-term blockages in the product.

Friction plate

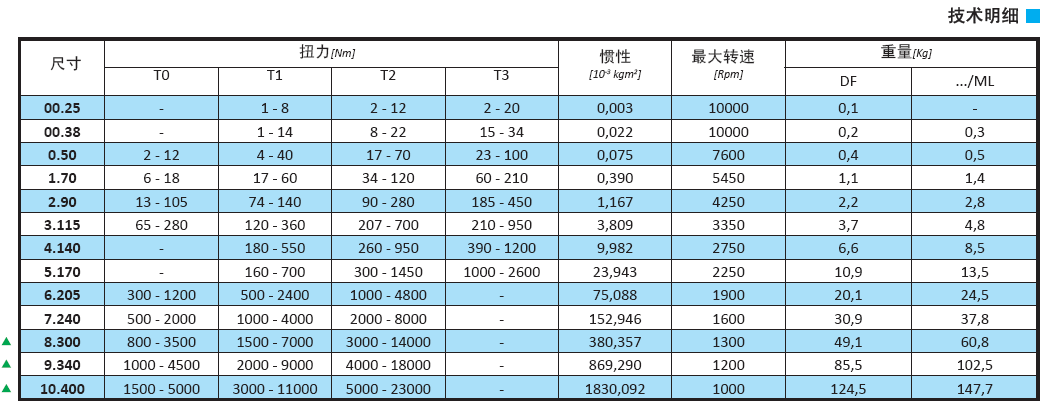

STD (Standard): The friction lining is suitable for the torque values indicated in the catalog. Torque/lifetime for optimum performance ratio.

LD (extended service life): The torque performance is the same as that of the standard friction plate, and the service life is extended by 5 times.

LDX (extra long service life): The service life is 150 times longer than the standard friction plate, but the torque performance is reduced by 70%.

main application

Molding machine

Transport machine

car

Agricultural machinery, woodworking machinery